HYDAC Process Filter

Process filter

The product range includes components for filtering low to high viscosity as well as gaseous media:

- Automatic back-flushing filters AutoFilt®

- Inline and screen basket filters in single and double versions

- Gas filters

- Filter elements (also customized designs)

- Filter systems and customized solutions

Process filter Liquids

Many industrial companies require different types of process and service water for their production and manufacturing processes. These include, for example, water for cooling purposes, washing and flushing water, seal water for rotary seals, service water to prepare chemical solutions etc.

Expert pre-filtration prevents subsequent expense:

- Improved service lives of fine filters and membranes downstream

- Lower maintenance costs as a result of longer service intervals

- Lower energy consumption

- Increased process reliability

- Reduced operating costs

- Guaranteed quality

Automat. back-flushing filters AutoFilt®

Automatic back-flushing / self-cleaning filters extend service life and maintenance intervals in process technology

Self-cleaning back-flushing filters, type AutoFilt® by HYDAC are automatic filters for industry and technology. They ensure the cleanliness of water, coolants and lubricants as well as lower viscosity fluids. The AutoFilt® filter range is very versatile and diverse and ideally suited for retrofitting in existing plants.

As a full-line supplier we offer the appropriate back-flushing filter for each application:

- Isokinetic filtering and back-flushing

AutoFilt® RF3 / RF4 / RF5 / RF7 - JetFlush Technology – Hydrodynamic suction

AutoFilt® RF10 / RF12 - Hybrid Technology - Centrifugal separator and inline filter

AutoFilt® ATF TwistFlow Strainer - Hydropneumatic back-flushing with secured media separation

AutoFilt® RF9 - HyStream finest filtration < 50 µm

AutoFilt® RF14

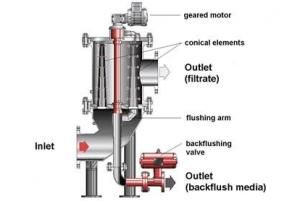

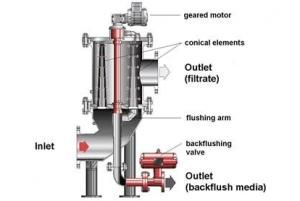

AutoFilt® RF3

Isokinetic Filtering and Back-flushing

For many years this has been the reliable solution in respect of automatic filters

Features

- Separation of solid particles from low viscosity fluids

- Filtration ratings from 25 to 3,000 µm

- Flow rates up to 7,500 m3/h

- Conical filter elements ensure maximum efficiency

- Flexible design of the filter housing

(The inlet and outlet flanges as well as the back-flushing line can be configured in different positions)

Advantages

- Fully automatic operation

- Ready-to-operate unit

- Maximum utilization of the filter area

- Already proven ist worth many thousands of times

- Isokinetic filtering and back-flushing

Areas of application

- Cooling water filtration

- Service water filtration

- Seal water filtration

- Protective filter before membrane, ozon and UV-systems

- Protective filter before nozzles and pumps

- Filtration of injection Water

- Filtration of flushing water (pipeline flushing)

- Conditioning of industrial water used to cool generators

- Water conditioning for cooling blast furnaces and rolling mills

AutoFilt® RF4

Tried-and-tested function principle – compact design

Features

- Separation of solid particles from low viscosity fluids (Coolant, Water)

- Filtration ratings from 25 to 3,000 µm

- Flow rates up to 385 l/min

- Conical filter elements for maximum efficiency

Advantages

- Compact design

- Fully automatic operation

- Ready-to-operate unit

- Maximum utilization of the filter area

Areas of application

- Filtration of coolant

- Protective filter high pressure pumps

- Protection of system components, for e.g. rotary joints, valves, tools, tool fixture

- Seal water filtration

- Service water filtration

AutoFilt® RF5

Self-cleaning automatic filtration using proven technology

Features

- Separation of solid particles from low viscosity fluids

- Filtration ratings from 25 to 3,000 µm

- Flow rates up to 4,200 m3/h

- Conical filter elements ensure maximum efficiency

Advantages

- Fully automatic operation

- Ready-to-operate unit

- Maximum utilization of the filter area

- Already proven ist worth many thousands of times

- Isokinetic filtering and back-flushing

Areas of application

- Cooling water filtration

- Service water filtration

- Seal water filtration

- Protective filter before membrane, ozon and UV-systems

- Protective filter before nozzles and pumps

- Filtration of injection Water

- Filtration for irrigation systems (e.g. drip irrigation)

- Filtration of flushing water (pipeline flushing)

- Conditioning of industrial water used to cool generators

- Water conditioning for cooling blast furnaces and rolling mills

AutoFilt® RF7

The self-cleaning automatic filtration solution for low installation height

- Space-saving horizontal design

- Pivoting lid device supplied as standard, for easy access to the inside of the filter

- Separation of solid particles from low viscosity fluids

- Filtration ratings from 25 to 3,000 µm

- Flow rates up to 7,500 m3/h

- Conical filter elements ensure maximum efficiency

Advantages

- Ideally suited to systems with limited space

- Fully automatic operation

- Ready-to-operate unit

- Maximum utilization of the filter area

- Isokinetic filtering and back-flushing

Areas of application

- Cooling water filtration

- Service water filtration

- Seal water filtration

- Sea water filtration

- Protective filter before membrane, ozon and UV-systems

- Protective filter before nozzles and pumps

- Filtration of flushing water (pipeline flushing)

- Conditioning of industrial water used to cool generators

- Water conditioning for cooling blast furnaces and rolling mills

AutoFilt® RF9

Hydropneumatic back-flushing with secure media separation

Features

- Back-Flushing driven by external fluid

- Large filter surface for ist compact size

- Low-maintenance, service-friendly design

- Filtration Ratings from 1 to 500 µm

- Flow rates up to 1,000 m³/h

Advantages

- Efficient back-flushing with secure media separation

- Large filter area in a compact design

- Reliable separation of media – filtrate and back-flushing gas not mixed together

- Cleaning without pressure drops

Areas of application

- Fuels

- Coolants

- Lubricants

AutoFilt® RF10

JetFlush Technology – Hydrodynamic Suction

Features

- Variable filter isometry

- Individual Control Parameter

- Filtration ratings from 40 up tp 3,000 µm

- Electro-pneumatic supply voltage

- Filter elements made of Stainless steel

- Corrosion protection for filter housing made of carbon steel: Polyurethane coating

Advantages

- Back-flushing independent of the pressure on the filter clean side

- Only depending on the inlet pressure

- Highly-efficient back-flushing even under low pressure conditions and with long back-flushing lines

- Due to its highly efficient back-flushing the filter is even suitable for high dirt loads and peaks in contamination

Areas of application

- Ballast water pre-filtration / Automatic filter ballast water treatment

- Scrubber Water Filtration

- Applications with low pressure conditions

AutoFilt® RF12

Compact automatic filter for coolants in self-supplied machine tools –

The efficient alternative to the cyclone separator

Features

- Highly efficient back-flushing mechanism based on conical JetFlush-technology

- Only depending on the inlet pressure

- Filtration ratings from 25 to 100 µm

- Flow rates up to 80 l/min

Advantages

- Energy-optimised filtration and back-flushing principle

- Independent of filtrate pressure

- Compact design

- Simple structure

- Simple integration and flexible adaptation to the machine

- Maintenance-friendly design

Area of application

- Separation of solid particles from low viscosity fluids

- Filtration of coolants in low-pressure range

AutoFilt® RF14

Fine Filtration - Basket filter Technology

Features

- Use as a pre-filter in Ballast water treatment Systems ( e.g. UV Systems)

- Basket-based, self-cleaning automatic filter

- Filtration ratings from 1 to 90 µm

- High cleaning Efficiency

- Variable filter isometry

Advantages

- Effective cleaning of the fine filter fabric

- Low rinsing water loss

- Low maintenance

Areas of application

- Pre-filtration of Ballast water

- Scrubber- water Treatment

- Treatment of cooling water

AutoFilt® ATF

Hybrid Technology - TwistFlow Strainer ATF

Coarse separation by centrifugal force with guaranteed filtration ratings

Features

- Suitable for wide variability in the quality of untreated water

- Copes easily with high contamination loads

- Degree of separation associated with a centrifuge separator combined with defined filtration ratings

- No transfer of contamination to the clean side

- Flow rates up to 400 m3/h

Advantages

- Consistent filtrat quality

- Continuous filtration – constant self-cleaning

- No turning parts – easy to service and low maintenance

- Available as system solution for higher flow rates

Areas of application

- Snow water treatment (protection of snow cannons and snow lances)

- Pre-filter to relieve sand filters

- Filtration of surface water

- Pre-filtration before membrane-, ozon-, UV-systems

- Pre-filtration before waste water treatment plants