HYDAC Filter Elements

THE HEART OF THE FILTER !

The operating fluid passes through the filter element and is thereby reliably relieved of solid particles and other fluids. Depending on the requirement and the hydraulic filter construction, various filter materials in surface or depth filters (coarse or fine filters), various filtration ratings (1 to 200 µm) and designs (return line/suction/pressure filter elements) are used.

ORIGINAL HYDAC FILTER ELEMENTS

YOU benefit from:

- GREATER SYSTEM AVAILABILITY from reliable filtration

- LONG ELEMENT SERVICE LIFE through highest dirt holding capacities

- HIGHER OPERATING DEPENDABILITY through outstanding cleanliness classes

- REDUCED MAINTENANCE COSTS through long replacement intervals

A - Elements subject to API

"A"-elements are used in AFLD filters subject to API 614.

FEATURES:

- Filtration rating: 10 μm

- Filter material: Optimicron® Power incl. Stat-Free® media

- Very low pressure drop

- Absolute filtration rating

- Operating temperature: up to 100°C

- Compatible with every established operating media

- Without by-pass valve

AM - Aquamicron

The element technology of the Aquamicron series (N5AM) is distinguished for its

- High dirt holding capacity of the glass fibre layers used and

- high water retention capacity

The glass fibre structure and the folded construction of the elements enables a high flow rate and thus

- high dedusting velocities through the high circulation rate

- a constant cleanliness level throughout the process cycle in conjunction with high and low rates of dirt penetration

- a lower initial differential pressure.

The Aquamicron elements bond the water by means of a chemical reaction. This is not reversible, i.e. the water will continue to be held in the element, even if there is a rise in pressure.

- Very high water retention capacity

- Very high contamination retention capacity

- Prolonged oil service life and oil cleanliness through ultrafine filtration.

Betterfit elements

HYDAC Betterfit filter elements secure the function and service life of important and expensive hydraulic components by means of their high quality standard. They exhibit the same quality and performance standard as original HYDAC elements.

Using the comprehensive HYDAC Betterfit database, it is easy to find the appropriate HYDAC replacement element for an element order code.

FEATURES:

- Filter rating: 3 to 25 µm

- Filter materials: glass fibre, solid plastic, wire mesh, paper, water-absorbent material

- Permissible differential pressures: 10, 20 or 210 bar

- Operating temperature: up to 100°C

- Compatible with all conventional operating media

D - Pressure elements

Type "D" elements are used in pressure filters, e.g. in the series DF, DFF, DFG, DFP, DFZ, DFDK, LF, MDF.

FEATURES:

- Filter rating: 3 to 200 µm

- Filter materials: glass fibre, solid plastic, wire mesh, metal fleece, plain dutch weaves, water-absorbent material

- Absolute or nominal filtration, depending on the filter material

- Permissible differential pressures: 10, 25, 30 or 210 bar

- Operating temperature: up to 100°C

- Compatible with all conventional operating media

- Without bypass valve (optionally with)

DH - Pressure elem. stainl. steel

Pressure filter elements in stainless steel versions are used in hydraulic filters which would normally be equipped with elements of construction type "D".

FEATURES:

- Filter materials: Betamicron (1 µm - 20 µm), Chemicron (1 µm - 20 µm), wire mesh (25 µm - 250 µm)

- Differential pressure: 210 bar

- Operating temperature: up to 400°C

DM - Dimicron

The element technology of the Dimicron series is distinguished for the high contamination retention capacity of the glass fibre layers used. The glass fibre structure and the folded construction of the elements enables a high flow rate and thus

- high dedusting velocities through the high circulation rate

- a constant cleanliness level throughout the process cycle in conjunction with high and low rates of dirt penetration

- a lower initial differential pressure.

- Very high contamination retention capacity

- Improvement of oil service life and oil cleanlines

DN - Pressure elements DIN

Pressure filter elements in accordance with DIN 24550 are used in pressure filters, e.g. in the series DFN, FLN, FLND, FMND, LFN, LFNF.

FEATURES:

- Filter rating: 3 to 200 µm

- Filter materials: glass fibre, wire mesh

- Absolute or nominal filtration, depending on the filter material

- Permissible differential pressure: 30 to 160 bar

- Operating temperature: up to 100°C

- Compatible with all conventional operating media

- Without bypass valve

- In accordance with DIN 24550

FM - Flexmicron

The cartridge filter elements of the Flexmicron series are used for solid particle separation in a wide different of applications.

The are distinguished by their enormous flexibility with respect to area of application, medium, filter rating and adapters. The product series offers the appropriate element for each application and is comprised of:

- Flexmicron P (Premium)

Pleated elements for applications with the highest cleanliness requirements - Flexmicron S (Standard)

Spun Spray elements for applications with high requirements with respect to fluid and type cleanliness - Flexmicron E (Economy)

Spun Spray elements for applications with medium requirements with respect to fluid and type cleanliness

For application on component cleaning plants, testing facilities, hydraulic and lubrication plants and for KSS cooling lubricants.

- High sequestration performances (up to 99.99%)

- Filtration rating 1 ... 90 µm

- High contamination retention capacity

- High media compatibility

- Wide adapter product range

- Commercially available element geometry Commercially available element geometry

L - Air filter elements

Elements of the "L" type can be used in filling and breather filters, e.g. in the series ELF, BF, LU.

FEATURES:

- Filter rating: 3 to 100 µm

- Filter materials: glass fibre, wire mesh, paper, water-absorbent material

- Absolute or nominal filtration, depending on the filter material

- Operating temperature: up to 100°C

- Compatible with all conventional operating media

MA - Spin-On cartridges

"MA" type cartridges are used in mobile filters of the MF and MFD series, in addition to breather filters of the BL series.

FEATURES:

- Filter ratings: 3 to 20 µm

- Filter materials: glass fibre, paper

- Absolute or nominal filtration, depending on the filter material

- Permissible differential pressure: 8 bar

- Operating temperature: up to 100°C

- Compatible with all conventional operating media

MU - Spin-On cartridges

"MU" type cartridges are used in mobile filters of the MF series, in addition to breather filters of the BL and BLT series.

FEATURES:

- Filter ratings: 3 to 20 µm

- Filter materials: glass fibre, paper, molecular sieve

- Absolute or nominal filtration, depending on the filter material

- Permissible differential pressure: 8 bar

- Operating temperature: up to 100°C

- Compatible with all conventional operating media

MX - Elements for MFX

Elements of the "MX" type are installed in the low-pressure filter MFX.

Integrated HYDAC Quality Protection protects against the installation of third-party elements, thus ensuring high replacement parts quality and operational safety.

FEATURES:

- Filter ratings: 5 to 20 µm

- Filter materials: glass fibre, solid plastic, meltblown

- Absolute filtration

- Permissible differential pressure: 10 to 20 bar

- Operating temperature: up to 100°C

- Compatible with all conventional operating media

R - Return line elements

R elements are used in return line filters, e.g. in the series RF, RFD, RFM, RFL, RFLD, RFM, NF, NFD.

FEATURES:

- Filter ratings: 1 to 200 µm

- Filter materials: glass fibre, solid plastic, wire mesh, paper, metal fleece, water-absorbent material

- Absolute or nominal filtration, depending on the filter material

- Permissible differential pressures: 20 bar

- Operating temperature: up to 100°C

- Compatible with all conventional operating media

- With bypass valve (optionally without)

RK - Return line-suction elements

RK elements are used in return line suction filters of the RKM series.

FEATURES:

- Filter ratings: 10 and 15 µm

- Filter material: meltblown

- Absolute filtration

- Permissible differential pressure: 20 bar

- Operating temperature: up to 100°C

- Compatible with all conventional operating media

- Without bypass valve

RN - Return line elements DIN

Return line filter elements in accordance with DIN 24550 are used in return line filters, e.g. in the series RFN, RFLN, RFLND, RFND.

FEATURES:

- Filter ratings: 3 to 25 µm

- Filter materials: glass fibre

- Absolute filtration

- Permissible differential pressure: 20 bar

- Operating temperature: up to 100°C

- Compatible with all conventional operating media

- Without bypass valve

- In accordance with DIN 24550

Optimicron®

Optimicron®

Innovative Filter Element Technology for Sustainable Filtration

HYDAC Optimicron® has a wealth of innovations and optimised features:

- Unique HELIOS pleat geometry

- Innovative, integrated drainage layer*

- New, upstream drainage layer*

- Efficient filter materials

- Expansion of the range of filtration ratings

- Optimised filter element wrap

Optimicron® will save you up to 30 % in differential pressure. This not only protects your pocket, but also the environment.

*) Designed for specific applications

Stat-Free® elements

Stat-Free® is the innovative element technology which protects your hydraulic and lubrication system safely against electrostatic charging.

FEATURES:

- Filtration ratings: 3, 5, 10, 15 and 20 μm

- Filter materials: Lubimicron, Betamicron®4, Mobilemicron

- Absolute filtration rating

- Operating temperature: up to 100°C

- Compatible with every established operating media

- Depending on element type with or without by-pass valve

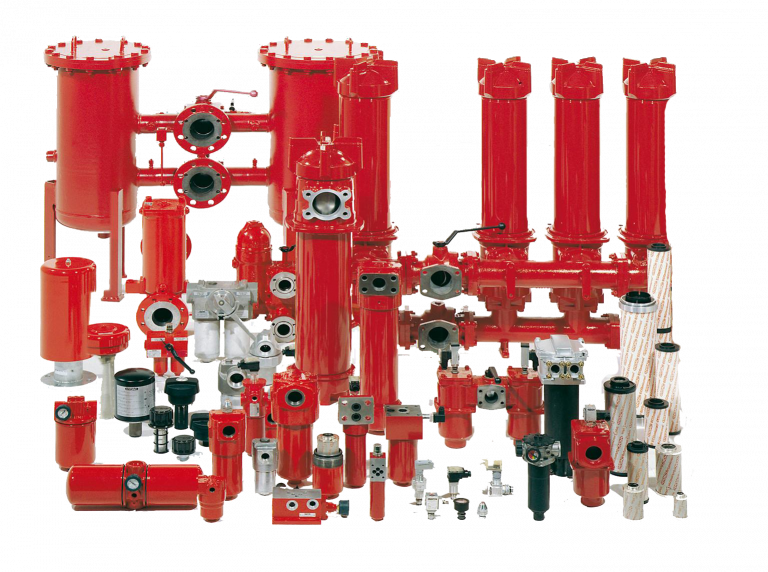

FILTRATION

Filtration Technology

Components and system for removing solid, liquid and gaseous contamination and water from hydraulic, lubricating, flame-resistant and biodegradable operating fluid.

Hydrac filtration products meet market demands:

- High particle removal over a wide different pressure range

- Low pressure drop, also for cold starts

- High Level of stability

- High Contamination retention, longer service intervals

- Reduced installation dimensions and machine-specific housing

- Ultra-modern laboratory and test rig technology

The Products

In-line Filters, up to 450 bar, Qmax = 15,000 l/min

Offline filters for extreme contamination filter elements,

Filter material: glass fibre, metal fibre, wire mesh, paper and incinerable all-plastic

Filtration rating: 3µm - 200µm

Clogging indicators: visual, lectrical, electronic

Tank breather filters,

Filtration rating: 3µm - 10µm

Stat-Free elements

Guaranteed reliablility thanks to Quality Protection

Diesel pre-filtration

Typical Applications

Oil hydraulics, Lubrication technology Machine tools, Plastics machinery

Foundry machines, Mobile machinery, Automotive, Steel construction

Hydro-Engineering, Mining, Off-shore, Ship-Building, Power Plant technology

Tranmission Systems, Paper mills, Stage / Platform Engineering All type of

Test Rigs Cleaning systems.