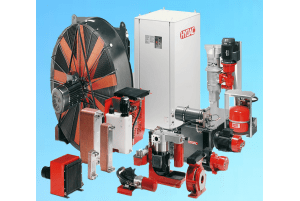

HYDAC COOLING SYSTEMS

Cooling systems

More safety through cool system solutions.

The heat arising from internal thermal loss in main spindles, drives, control cabinets, cooling lubricants and hydraulics can be channelled away very effectively by fluid cooling.

Using HYDAC cooling systems with air cooling, water cooling or compressor cooling allows all requirements to be fulfilled and a constant cooling temperature to be achieved.

Refigerator units

The RFCS refrigerated fluid chiller system allows various fluids such as water, water glycol and oil to be cooled at or below ambient temperature. The chiller consists of refrigerator, pump, tank and controller and is able to set the temperature of the operating fluid to a previously configured target value independently.

The energy-efficient, patented mixer principle, combined with a sealless immersion pump, makes this system the ideal component for your machine tool.

- Target temperature can be set at or below ambient temperature

- Leak-free immersion pump

- Compact dimensions

- User-friendly controller interface

- Cleanable air filter

- Plug & Play solution

- Easy to service and user-friendly

Features:

- Fluid cooling system as separate auxiliary cooler or for integration into a machine

- Cooling capacities from 1 to 160 kW

- Can be used for any cooling tasks

- Stand-alone control of the system by means of innovative controller design

- Condenser available as water-cooled or air-cooled variant

- Several cooling circuits possible

Fluid-air cooling systems FLKS

The FLKS is a compact fluid-air cooling system with a plastic tank, circulating pump, heat exchanger and fan for cooling circuits with water-glycol or mineral oil.

Function:

The pump conveys the operating medium from the tank through the component that is to be cooled. The fluid absorbs heat from the component and then flows back to the heat exchanger, where it is returned to a cooler temperature by the air flowing from the installed fan.

- Cost-effective and efficient cooling system

- Sizes FLKS-1, FLKS-2, FLKS-3, FLKS-4 and FLKS-5 with plastic tank housing with integrated fan

- Sizes FLKS-8 and FLKS-10 for especially high performance and high flow rates

- Energy-efficient thanks to optimized and adjusted drives and the heat being released directly to the surroundings

- Speed-controled systems:

The temperature of the operating fluid is controlled by adjusting the fan speed with a set difference to the ambient temperature.

The speed control is integrated as standard for sizes FLKS-8 and FLKS-10.

Technical data:

- Cooling capacity: up to 4.5 kW/K (ΔT10K = 45 kW)

- Flow rate: up to 300 l/min

- Tank content: up to 110 l

- Cooling medium: air

- Operating medium: water-glycol or mineral oil

Typical applications:

- Liquid-cooled drives: motor spindles, torque motors, servo motors, linear motors

- Inverter cooling

- Gearbox cooling and lubrication

- Bearing cooling

- Tool cooling

3D models are available on request. Please get in contact with us

Fluid-water cooling systems FWKS

The FWKS is a compact fluid-water cooling system for cooling and lubrication circuits with a plastic tank with circulation pump, a plate heat exchanger and additional accessories.

This system is primarily used as a temperature-controlled intermediate circuit. In this way the contamination and corrosion in the coolant circuits which could arise as a result of directi cooling with poor water quality is prevented.

Function:

The pump conveys the cooled operating fluid from the tank through the component that is to be cooled. Once there, it absorbs the heat. It then flows back to the plate heat exchanger, where it is returned to a cooler temperature by the cooling water.

Technical data:

- Cooling capacity: up to 250 kW (depending on the limiting conditions)

- Flow rate: up to 300 l/min

- Tank content: up to 110 l

- Cooling medium: water

- Operating medium: water-glycol or mineral oil

Typical applications:

- Liquid-cooled drives: motor spindles, torque motors, servo motors, linear motors

- Inverter cooling

- Gearbox cooling and lubrication

- Bearing cooling

- Tool cooling

3D models are available on request. Please get in contact with us.