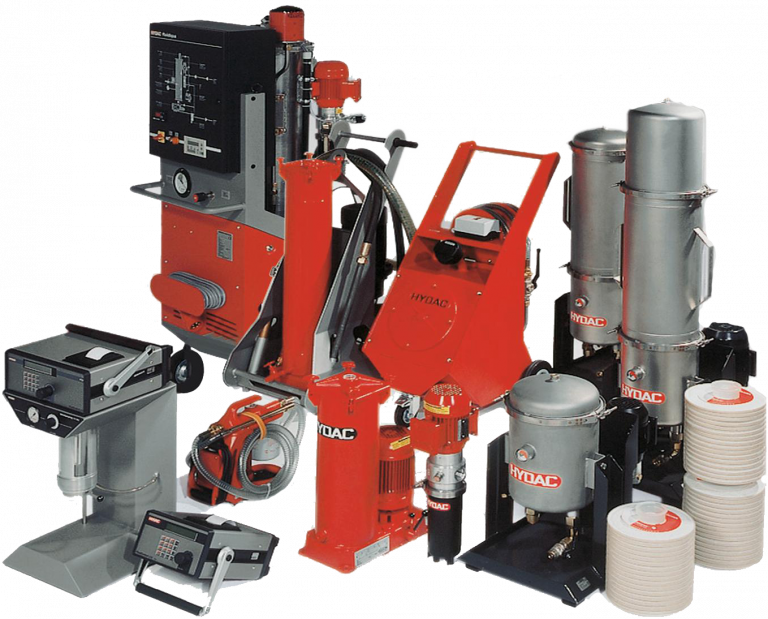

Mobile Filtration Systems

With the mobile filter systems, HYDAC offers an extensive product range of professional solutions for hydraulic servicing and maintenance. They are used for the filtered filling and/or repumping of hydraulic and lubrication media, for flushing at the time of startup or for continuous offline filtration. Convenient mobile devices are used for the separation of solid particles (with or without integrated fluid sensors) on several plants at once:

- Portable filtration units

- Mobile filtration units

- Clean filling and flushing

- Flexible utilisation on different plants

- Relieved load on the main flow filter

- Increased system availability

- Increases the service lifetime for hydraulic and lubrication media

- Reduction of Life Cycle Cost

FT 5

The barrel transport and filtration cart FT 5 is a mobile oil servicing and care unit used for filtration during the filling of plants and when repumping hydraulic and lubrication media. The unit is intended for carrying along a standard oil barrel (200 l). A switch on the unit enables simple changeover between pumping operations with and without filtration. For utilisation on hydraulic and lubrication oil plants in different industries.

- Flow rate: max. 30 l/min / 40 l/min

- Operating pressure: 4.5 bar

- Convenient filtration in bypass flow

- Safe and simple transport of a 200 l standard oil barrel

- Simple handling

- Filling with defined oil cleanliness

- Increased system availability

- Reduction of Life Cycle Cost LCC

TW 5

The oil transport and filtration cart TW 5 is a mobile oil servicing and care unit used for the transport of oil and for filtration during the filling of plants and when repumping hydraulic and lubrication media. The device is equipped with an integrated 200 l tank. A switch on the unit enables simple changeover between pumping operations with and without filtration (optional).

For utilisation on hydraulic and lubrication oil plants in different industries.

- Tank size: 200 l

- Flow rate: max. 30 l/min / 40 l/min

- Operating pressure: max. 4.5 bar

- Safer and simpler oil transport

- Convenient filtration in bypass flow

- Simple handling

- Increased system availability

- Reduction of Life Cycle Cost LCC

FCM

The FluidCleaner Mobil FCM is a mobile oile servicing and care unit and is used for offline filtration during the filling of plants and when hydraulic and lubrication media are being repumped. With the FCM, HYDAC is offering a flexible and dependable service device for fluid care and servicing which considerably increases the lifetime of operating media, components and thus entire plants and thereby reduces operating costs. For utilisation in hydraulic and lubrication oil plants in different industries (e.g. machine tools, plastic injection machines, paper machines, construction machines, steel industry, marine and offshore, mobile industry)

- Flow rate: max. 100 l/min

- Operating pressure: pmax = 10 bar

- Viscosity range: max. 15 ... 1000 mm²/s

- Avoidance of cost-intensive component damage and system downtimes

- Safe and convenient handling

- Increased oil service lifetimes

- Reduction of Life Cycle Cost LCC

FCC

The FluidCarrier Compact FCC is developed for the servicing of processing machines with tank volumes of up to 200 l. Special care must be taken to ensure at the time of the introduction of TPM (Total Productive Maintenance) that the filtered topping up of hydraulic and lubrication oils is guaranteed and that a mix-up between different types of oils is excluded. The FCC offers the possibility of transport and of the filtered filling of topping-up quantities, in addition to measuring points for the connection of particle counters (FCU) for monitoring oil cleanliness. Smaller systems can be dedusted in the bypass flow with the integrated filter unit (OLF 5). In addition, there is also the option of connecting a flow meter for documenting the quantity dispensed.

- Flow rate: max. 15 l/min

- Operating pressure: 3.5 bar

- Viscosity range: 15 ...1000 mm²/s

- Safe and simple transport: 70-litre volume for filling small units, simple handling

- Filtered filling: via OLF 5 (ß2 >1000), resulting in fewer downtimes caused by fresh oil contamination

- Monitoring: FCU and flow meter optional, therefore documentation of the quantity and/or cleanliness, respectively, by maintenance

- Mobile offline filtration unit: can also be used for offline filtration

OFU

The Filter Repumping Unit OFU is used as a mobile oil servicing and care unit for filtration during the filling of plants and when hydraulic and lubrication media are being repumped. Utilisation on hydraulic and lubrication oil plants in different industries.

- Flow rate: max. 100 l/min

- Operating pressure: max. 10 bar

- Convenient filtration in bypass flow

- Simple handling

- Increased system availability

- Reduction of Life Cycle Cost LCC

OF 5 mobile

The mobile filter unit OF 5 mobile is used for filtered filling and emptying, for offline filtration and for the unfiltered pumping-out of hydraulic and lubrication oils. The mobile filtration unit can be optionally equipped with the ContaminationSensor CS 1000 for simultaneous monitoring of the solid particle contamination in the oil. Utilisation on hydraulic and lubrication oil plants in different industries.

- Flow rate: max. 30 l/min / 40 l/min

- Operating pressure: 4.5 bar

- Convenient filtration in bypass flow

- Simple handling

- Increased system availability

- Reduction of Life Cycle Cost LCC

OF 5 C

The mobile filter unit OF 5 C mobile is used for filtered filling and emptying, for offline filtration and for the filtered pumping-out of hydraulic and lubrication oils. The integrated FluidControl Unit FCU 2000 measures particulate contamination while doing so, thus contributing to the monitoring of oil cleanliness. Utilisation on hydraulic and lubrication oil plants in different industries.

- Flow rate: max. 40 l/min

- Operating pressure: 4.5 bar

- Convenient filtration in bypass flow

- Simultaneous monitoring of the particulate contamination

- Simple handling

- Increased system availability

- Reduction of Life Cycle Cost LCC

MFU

The MFU 15 MobileFiltration Unit is used as a portable service unit for filling hydraulic systems, flushing small hydraulic systems as well as for cleaning in bypass flow. Solid particle contamination as well as free water can be removed by the filter elements. The MFU 15 can also be fitted with a CS 1000 ContaminationSensor. This allows the solid particle contamination in the oil to be monitored at the same time. The cleanliness class results are displayed according to ISO, SAE or NAS classifications.

- Improvement in service life for components and system filters

- Increased oil service life

- Increased machine availability

- Simple operation

- Compact design

- Integrated dry running protection

FILTER SYSTEMS

Filter System Technology

Mobile and stationary components and equipment for:

Separation of solid, gaseous and liquid contaminants from hydraulic fluids, lubricating

oils and emulsions.

Extended maintenance intervals and service life of operating media.

Monitoring, analysis, diagnostics and documentation of operating conditions for original equipment

and for retrofitting machines and systems.

Condition monitoring using fluid sensors

The Products

Filling units, Offline units OLF, Automatic filtration units, Dewatering systems FAM

Contamination controllers FCU, Oil condition sensors CS, Water sensors AS, Transformer care units TCU

Digital analysis equipment Portable data recorders, Sampling equipment, Measuring and analysis Kits

Typical Applications

Iron and Steelworks, Wind Turbines, Foundry equipment, Cement works, Paper mills, Large Tranmission

Turbines, Large compressors, Contruction, Agricultural, Forestry machinery, Plastics Processing

Machine tools Off-shore, shipbuilding Transformers